I have many fond memories of this time of my life. It was the 1960’s, we were eight years old and pals forever. The six of us young boys, my tribe, were elementary and middle school classmates and graduated together from the same high school a decade later.

The medicine men in our tribe were Steve’s father who was a doctor and administrator of the hospital where I, and probably all six of us were born. His signature is on my birth certificate. Bill’s dad was a family practice doctor and my father’s physician from that time until my dad’s death in 1991.

We six boys became men, each successful in his own right. Here’s how we applied what we learned.

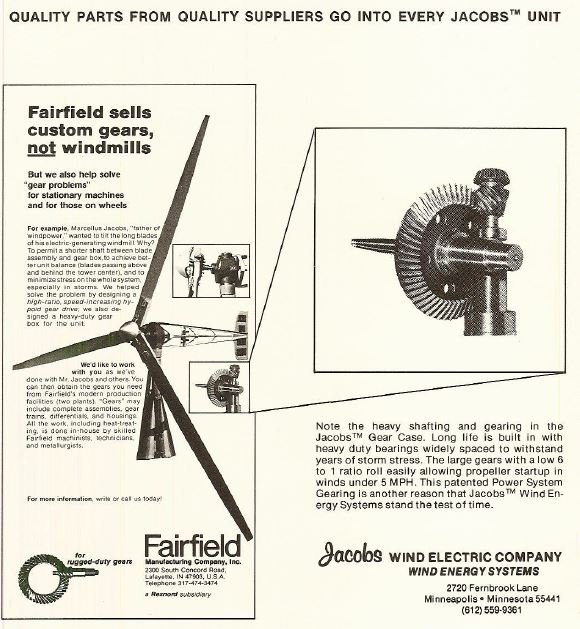

As my regular blog readers know, I am a Purdue-educated mechanical engineer. I began my career in the gear company that my grandfather started in South Bend, Indiana back in the ‘30’s. Then, I was the long-time chief engineer at the largest gear and geared products company in North America. It 2018, that company sold for $600 million. After that, I started my own power transmission design engineering consulting company, which is what I do now.

Steve became a doctor and works at the Mayo Clinic in Rochester, Minnesota as a diagnostic radiologist.

Bill, after serving in the Air Force, also became a doctor and works in emergency and urgent care medicine in southern Illinois.

Larry, a graduate of both Notre Dame and Harvard, took over his father’s overhead crane company, expanded it and sold it in 2012. He then became executive director of The Crane Certification Association of America. Today, he is a consultant to the overhead crane industry.

Jim became general manager of the Dodge division of Chrysler Corporation, then vice-president and head of its Motorsports Division. He left Chrysler to become president of the Sports Car Club of America (SCCA).

Dean, a perpetual motion machine who loved sports and played almost every sport in high school, formed a sports marketing company and organized hundreds of half-marathons around the country.

Although all of us achieved success in our chosen endeavors, I am amazed that of the six of us in my tribe, four ended up in our father’s, or in my case my grandfather’s and uncle’s business and/or profession. That is two doctors, like their dads; and two in a technical and engineered product field; (one in overhead cranes and one in gears and gearboxes). Jim’s father was an engineer at the same company where my father worked, and Dean’s father owned a construction company, but they both ended up as businessmen.

When I had a son of my own and it became my time to pass along the tradition, my son David and I joined Indian Guides. There were two lawyer fathers in our tribe, and although we were known as the Sioux tribe, it was not the “Sue as in lawsuit” tribe. I’m sure that the name was just a coincidence. I enjoyed sharing the Indian Guide experience with my young son and passing along the traditions and fond memories that I made with my own dad.

The lesson here is that we as people are always setting an example for others, and teaching them; sons, daughters, co-workers, and the next generation, peers and those we formally mentor. This is either by our actions or just by the way we live our lives. Others observe us and pay attention to what we are doing or not doing, and it has an impact — hopefully a positive one.

To paraphrase Apple founder Steve Jobs, we all put our own dent in the universe and add to the flow of life. We are all passing along our accumulated knowledge and experience to others. May we do it well.

I will leave you with this the song we used to sing all those years ago: Pals Forever which is sung to the tune of Clementine.

Pals forever. Pals forever. That’s our slogan. That’s our song.

Boys are stronger. Dad’s feel younger, when they take the boys along.

Dads are for it. Moms adore it. And the boys all think it’s fine.

Pals forever. Pals forever. Y Guides will have good times.

Through the days and through the years, we will wander side by side.

Pals forever. Pals forever. The Great Spirit as our guide.